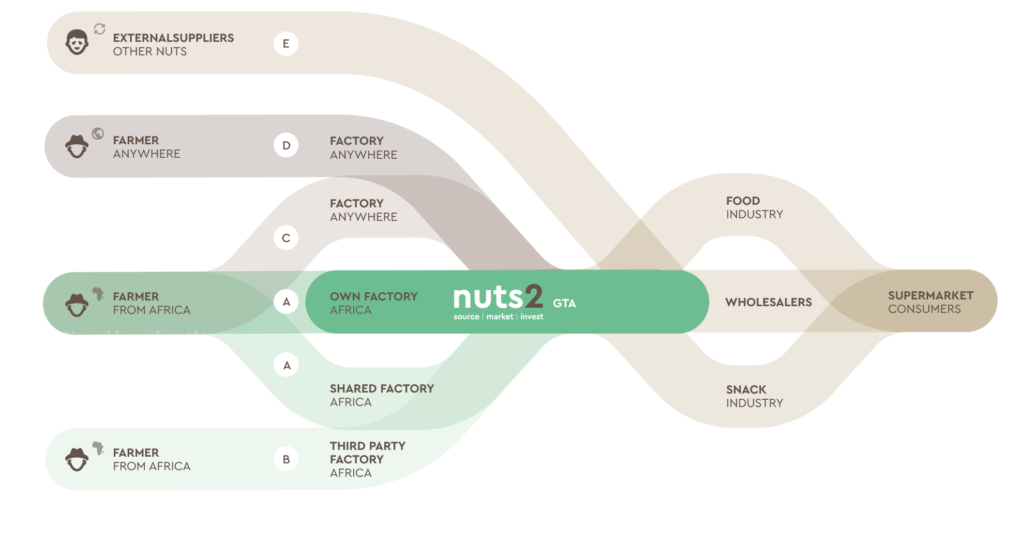

We operate 4 different supply routes:

- A-route: Purchases from African farmers, processed in our own local factories. This route offers the best control over fair trade practices.

- B-route: Purchase from African farmers, processed in third party African factories. This allows us to diversify but also to extend our impact through other African processors.

- C-route: Purchases from African farmers, processed in Asian factories. This route helps us to develop markets for future African factories or when we are short in local production capacity.

- D-route: Sourcing from Asian factories, of nuts of origin from anywhere. This route is used to develop market..

Boeren voorzien van een betrouwbaar afzetkanaal

When Gerard Klijn came to Burkina Faso for the first time in 2010, he met with farmers, chopping down their cashew trees for fire wood. Revenues from cashew were neglicable and the market highly unreliable. The investment in a local processing facility provided jobs of course, but equally importantly it provided a reliable market outlet for the farmers.

In Afokantan we are working on a long term, sustainabel relationship through our values of Integrity, Respect, Unity, Passion and Innovation.

Charles Kayembe, MD Afokantan

Improving farmer income

In addition, agricultural best practices training and support in obtaining organic and fair trade certification have provided farmers with a solid and improved source of income, as cashew is often a supplement to other crops.

“Employment at our factories means that workers receive a fair salary, health insurance and they can feed their families. Local economies are supported by the monthly salaris being spent. The honor of having a job, receiving training on the job allows people to dream. It gives hope for a better future.”

Ronald Zaal, Sourcing Director

Jobs in our factories

In our factories we work with a small core team of permanent contract employees and a large number of seasonal workers. The better we utilise the factory the more seasonal workers we can deploy. This is why we express the employment rate at the factories in Full Team Equivalent.

And, even though mecahnisation is important for cashew processing factories in order to stay competitive in the international markets, our factories continue to rely on our manual workers, of which about 75% is female.

What gets measured, gets done: applying western management principles helps us to achieve operational excellence.

Harm Voortman, MD Anatrans

Zorg voor de planeet

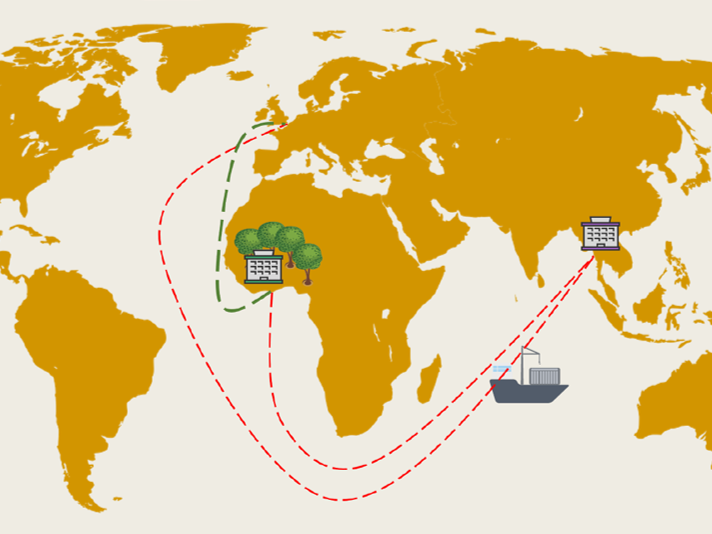

90% of African cashew (close to 60% of the world production) travels all the way to Asia to be shelled, peeled and packed. Only then they travel back to be consumed by you

See the red route.

Nuts2 aims to maximise the amount of cashew processed in Africa, first and foremost to provide jobs and economic growth, but in the process we save an awful lot of CO2. 90% to be precise. That is 9.000 kgs of CO2 saved per container shipped.

See the green route.